Energy Efficient Custom Homes

Insulated Concrete Forms.

Build an energy-efficient, durable and high performing custom home.

How do Insulated Concrete Forms (ICF) work?

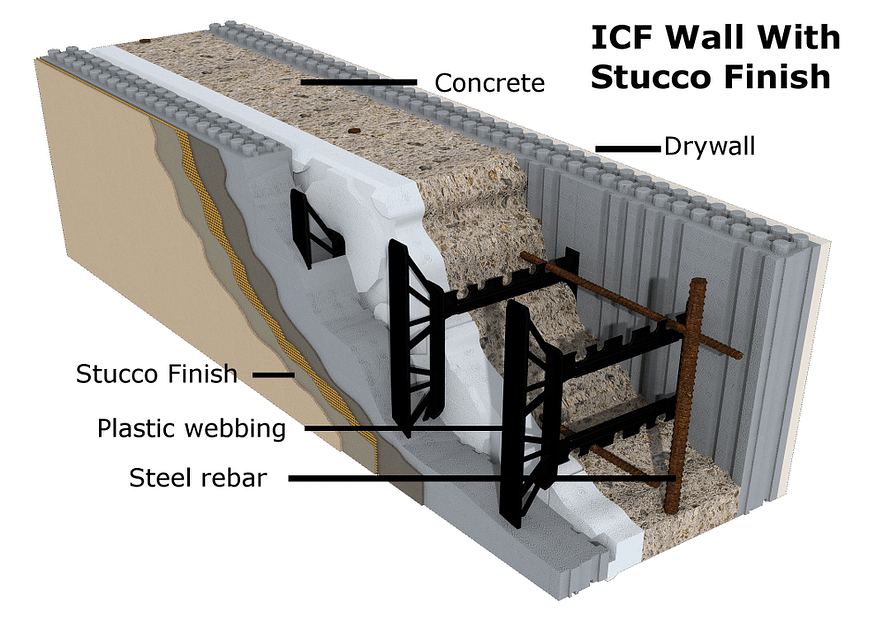

Insulated Concrete Forms (ICF) are a system of formwork for reinforced concrete made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors, and roofs.

The forms are interlocking modular units that are dry-stacked (without mortar) and filled with concrete. The units lock together somewhat like Lego blocks and create a form for the structural walls or floors of a building.

ICF construction has become commonplace for high performance residential, and commercial construction as more stringent energy efficiency and natural disaster resistant building codes are adopted.

Key Characteristics of Insulated Concrete Forms

No air leaks, which improves comfort and reduces heat loss compared to walls without a solid air barrier.

· High thermal resistance (R-value) typically above R-24 this results in saving energy compared with un-insulated masonry.

· Continuous insulation without thermal bridges or "insulation gaps", as is common in framed construction.

· Thermal mass, when used well and combined with passive solar design, can play an important role in further reductions in energy use, especially in climates where it's common to have outside temperatures swing above inside temperatures during the day and below at night.

ICF walls have much lower rates of acoustic transmission. Standard thickness ICF walls have shown sound transmission coefficients (STC) between 46 and 72 compared to 36 for standard fiberglass insulation and drywall.

The level of sound attenuation achieved is a function of wall thickness, mass, component materials and air tightness.

Because the entire interior space of ICF walls is continuously concrete filled (no gaps as can occur between blown or fiberglass insulation and a wood frame wall) they pose more difficulty for casual transit by insects and vermin.

Additionally, while plastic foam forms can occasionally be tunneled through, interior concrete walls create a much more challenging barrier to insects and vermin than do walls made of wood.

Because they are constructed without a sheet plastic vapor barrier, ICF walls can regulate humidity levels, mitigate the potential for mold and facilitate a more comfortable interior while maintaining high thermal performance.

Insulated concrete forms create a structural concrete monolithic wall that is up to ten times stronger than wood framed structures.

· Structural integrity for better resistance to forces of nature, compared to framed walls.

· The components of ICF systems - both the poured concrete and the material used to make the ICF - do not rot when they get wet.

ICF walls have a four- to six hour fire resistance rating and negligible surface burning properties.

It takes about a quarter of an hour for a wood-frame home to catch fire. Because Insulated Concrete Form are tested up to 2000 degrees Fahrenheit (which is typical in a common house fire), subjecting wood walls to comparable heat, they typically collapse within 30 minutes

Essentially, walls made out of concrete prevent fire from spreading to the inside of the home. Wood, however, allows both heat and flames to pass through to start a fire, which is why they collapse so quickly.

ICF walls can be made with a variety of recycled materials that can minimize the environmental impact of the building.

What are the main benefits of Insulated Concrete Forms (ICF)?

Over the life of your custom home, Insulated Concrete Forms (ICFs) provide your home with lower hydro costs and excellent consistency in performance for your home compared to the traditional plywood frame building process.

You save money and don't have to go through additional unnecessary steps like you would using the traditional building method.

In terms of your custom home design and working with your architect, insulated concrete forms provide them with more flexibility as well opening up to you any idea you can imagine for your dream home, without worrying about restrictions to your specifications

What is the building process for Insulated Concrete Forms (ICF)?

ICF walls are constructed one row at a time. As the wall rises, blocks are staggered to avoid long vertical seams. Steel reinforcement (rebar) is placed vertically and horizontally. Structure frames known as bucks are placed around openings to give added strength to the openings and to serve as attachment points for windows and doors.

Interior and exterior finishes and facades are affixed directly to the ICF webs. Brick and masonry facades require a 'brick ledge' at the main floor level. Interior ICF polystyrene wall surfaces are ready for drywall installation.

Concrete placement for ICF forms is best accomplished with a concrete pump. Authentic Homes Inc. has an extensive range of equipment that is used to build your home.

We build and renovate all year round using insulated concrete forms

A custom home and swimming pool built by Authentic Homes Inc. using Insulated Concrete Forms (ICF)

Project Request Contact Form

Tell us about your custom home project!